In order to create certain products, a combination of blending or mixing must be administered. Whether they’re dairy products, foods or chemicals, they all typically consist of a mixture of ingredients. However, as you likely know, the aforementioned don’t become end products just by manually mixing different dry and liquid ingredients. Not only would that be inefficient, but it would also be problematic. That's where mixing and blending equipment come into play, as these machines permit processors to create large quantities of product in an efficient and accurate manner.

Powder Mixing: The Basics

Think of your home countertop blender. While you use this to process liquids - and usually not dry powders - the process is similar. To make certain drinks in the blender for instance, you're likely adding milk, fruits and more to it, then punching the button to create a homogenous end product. Powder mixers work similarly to that of your home blender, just on a much larger and more advanced scale. Just as how the blade within the home blender works as the agitator to help create the final product, there are a number of different agitators that are typically used in powder mixing equipment that are designed to perform a similar role.

Mixing can be done with all solid materials, with both solids and liquids and with gas and liquids. Below are some examples of common mixing and blending applications, as the process is one of the most demanding in several industries:

- Chemical processing: Whether it's fertilizers, specialty chemicals or both liquid and powder detergents, mixing may be the most important aspect of the chemical processing field.

- Pharmaceutical: Combining various different products to create medicine and drugs is often performed by blending for pharmaceutical purposes.

- Food: Cake mixes, rice, spices and flavoring are common examples of mixing and blending involved in food processing.

While there are many different types of mixers, there are a few broader styles that they are associated with. For instance, many mixers are classified as "continuous," as they are able to operate efficiently, and their final processed product is not limited to just batches of product. For processing plants that are aiming to improve their output or grow their operations, a continuous mixer is an absolute must have.

Shear blending and inline induction are other techniques and processes that can help with the blending of materials.

Common Powder Mixers (and Their Ideal Uses)

The end product is often only as good as the process, and it's important to note the differences in the various types of powder mixers and what applications and industries they are ideally used in. Here's a closer look at these different mixers and when they are ideally used in processing:

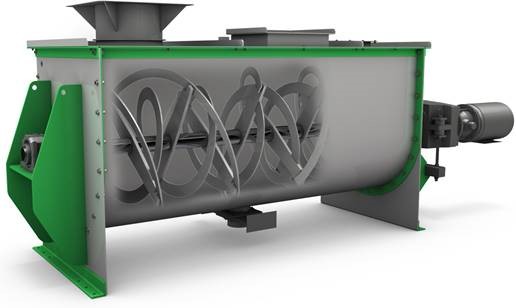

- Ribbon blenders: Ribbon blenders are ideal when mixing powder and granular ingredients is necessary. For this reason, these types of machines are common in the food industry, especially when it comes to processing food in bulk quantities. Ribbon blenders get their names from the pattern that describes their blades, as they resemble that of a ribbon.

- Paddle blenders: Just like ribbon blenders, paddle blenders are often characterized by the paddle-like blades that help process material. The paddles work by moving product from the bottom of the machine's trough and into the product stream. Because of the way that paddle blenders work, they're ideal for mixing product that is dissimilar in size and in shape. It's also worth noting that "hybrid" blenders exist that combine the paddle and ribbon blending styles.

- Twin shell (V-Blenders): Twin shell blenders, also commonly referred to as "V-blenders" for their V-like shape, are used to mix solids with solids and solids with liquids. The machines consist of two blending shells (one on each side of the V) that are then connected and come together at the tip of the V. Because of the V shape, twin shell blenders are able to perform very efficient blending. This is especially true when you consider the fact that the V chamber rotates as it works, which makes blending all the more thorough.

- Double cone: When it comes to blending flowing solids, double cone blenders are used almost exclusively for such purposes. Like the twin shell blender that we mentioned above, the solids that are being processed in the double cone blender are constantly mixed as the machine rotates for up to about 10 minutes a cycle. Double cone blenders are available in a variety of different sizes to allow processors to best select the unit for the application they are working to process.

- Zig zag blenders: Zig zag blenders are a style of continuous blender that's able to process liquids, solids and slurries. Designed for high volume production, zig zag blenders are ideal for gentle and more intimate processing. Zig zag blenders get their name, as the machine takes on a winding pattern to process the product inside of it.

- Nauta mixers: Nauta-style mixers are ideal for processing both solids and paste materials. These mixers are considered to be "connective" and work by gently mixing the material using only a small amount of heat. Because of the mixing style, there's little to no end product distortion. Another big advantage of the nauta mixer is that it is very economical. It uses very little power compared to the vast amount of material it is able to process at a time.

Other Blending Styles

There are a few other broad blending styles to make mention of, such as horizontal shaft mixers, tumble blenders and vertical screw mixers. Here's a brief overview of each:

- Horizontal shaft mixers: These mixing systems typically operate with either paddles or ribbons. They work, as the name implies, in a horizontal manner and are typically deployed for heavy-duty blending, such as spices, concrete and other wet and dry materials.

- Tumble blenders: Twin shell blenders are an example of a tumble blender, in that these types of mixers operate at fairly slow speeds and use diffusion for mixing solids.

- Vertical screw mixers: These types of mixers use heat and friction to help achieve the end result. Unlike horizontal mixers, these machines work vertically and these are also typically very large pieces of machinery.

What type of mixer is right for your processing facility? For more information on the various different types of powder blending equipment and accessories, and to enter your bid for a piece of quality used equipment, contact Bid on Equipment today.